Vertical scissor lift tables

Vertical Scissor Lift Table for Efficient Vertical Lifting

A vertical scissor lift table is a vital component in industries that require the efficient and safe movement of heavy loads. These tables are specifically engineered to streamline the handling of materials within manufacturing, warehousing, and distribution settings. By utilizing a hydraulic lift table, workplaces benefit from smooth and dependable vertical lifting, which helps to mitigate workplace injuries while significantly improving productivity. To explore a wide selection of these solutions, visit the lift tables page.

Engineered for stability, the vertical scissor lift table can support a variety of load sizes and weights. Its compact footprint makes it ideal for locations where space is limited, without sacrificing performance or load-bearing capability. The adaptability and robustness of vertical lift tables make them a preferred solution for settings that demand reliability and flexibility in material handling. For businesses seeking specific models that work well in confined spaces, the vertical scissor lift tables category offers several specialised options tailored to high precision environments.

The vertical scissor lift table is particularly beneficial for operations that require frequent, precise, and repeatable adjustments in elevation. This equipment enables consistent height positioning, which is crucial for tasks involving assembly, storage, or inspection. By integrating this type of scissor lift, workplaces experience streamlined workflows, better ergonomics, and a clear enhancement in operational safety.

What is a Vertical Scissor Lift Table

A vertical scissor lift table is designed to facilitate the raising and lowering of heavy items with ease. Its core mechanism relies on hydraulics, featuring a sturdy platform supported by a scissor structure and a hydraulic system. The architecture ensures that the table can handle significant loads while maintaining balance and stability throughout the movement, which is fundamental in settings that involve repetitive material handling.

Vertical scissor lift tables are commonly found across diverse industries, such as manufacturing, logistics, warehousing, and the automotive sector. Their role lies in simplifying transitions between elevations, making the transfer, assembly, or inspection of heavy equipment much more straightforward and efficient.

The standard configuration includes a reliable platform, the iconic scissor mechanism, and a hydraulic system that work in concert to provide dependable vertical lifting. These components have made the vertical scissor lift table an industry staple for improving both productivity and workplace safety.

How Does a Hydraulic Lift Table Work

A hydraulic lift table utilizes fluid dynamics to accomplish vertical lifting. The system’s core element is the hydraulic pump, which pushes hydraulic fluid into a cylinder. This action increases pressure inside the cylinder, causing the scissor mechanism, built from crossed arms, to extend and thus elevate the platform. When the operator releases the pressure, the hydraulic fluid returns, the arms contract, and the lift table smoothly descends.

This system enables controlled, powerful vertical lifting that is essential for material handling where precision and strength are necessary. The reliability of hydraulic lift tables, including the double scissor lifting table configuration for additional height, positions them as preferred choices in industries such as logistics, production, and maintenance. The controlled ascent and descent reduce risks to personnel and allow accurate positioning of heavy loads during daily tasks.

Key Components of a Scissor Lift Table

Understanding the main parts of a scissor lift table helps illustrate why they are such effective vertical lift solutions. At its core, a scissor lift table consists of a durable platform secured by a scissor mechanism. The scissor structure, made from robust steel supports crossing in an “X” shape, creates the vertical motion by opening and closing via hydraulic or sometimes pneumatic cylinders.

The hydraulic system powers the upward and downward movement, ensuring load control and smooth operation. The base frame anchors the table, maintaining overall stability during even the most strenuous linear or vertical lifting applications. Together, these components allow the scissor lift table to adapt to a variety of industrial requirements, making it a versatile choice for modern workplaces.

Industries Using Vertical Scissor Lift Tables

Numerous industries rely on vertical scissor lift tables for efficient, productive, and safe handling of heavy or bulky materials. Manufacturing settings integrate these tables into assembly lines, facilitating the transport and alignment of components. Warehousing environments use lift tables to reach different inventory levels quickly, adapting to various storage systems and maximizing floor space.

Automotive workshops employ scissor lift tables to create ergonomic workstations for vehicle maintenance, minimizing strain and enhancing technician productivity. In the construction industry, vertical lift tables are used to supply materials at varying heights, ensuring safety and reducing manual handling. Retail operations leverage these tables for effective organization, seasonal changeovers, and restocking at elevated shelves.

Each sector gains significant operational benefits by implementing vertical scissor lift tables, such as increased efficiency, reduced physical risk, and improved workflow. These tables are recognized as essential tools for safe and effective vertical lifting wherever repetitive handling or significant load weight is present.

Benefits of Hydraulic Scissor Lift Tables

Hydraulic scissor lift tables present a range of advantages in industrial and commercial contexts. By leveraging hydraulic fluid power, they ensure fast and reliable lifting for heavy loads. Workflow efficiency is enhanced as staff spend less time manually handling materials and more time focusing on value-added tasks.

One of the most significant benefits is the reduction in manual effort, which translates to lower injury risks among staff. A hydraulic lift system provides consistent, controlled movement, with high load capacities allowing operators to move large quantities at once. The precision offered by these tables allows for accurate height positioning, which is critical for delicate assembly tasks or inventory management. For applications requiring substantial capacity and additional stability, consider exploring tandem scissor lift tables.

How Hydraulic Lifts Improve Workplace Efficiency

The integration of a hydraulic lift or lift table into daily operations brings about substantial gains in productivity. These tables reduce the need for repetitive manual lifting, lessening the physical strain on employees and minimizing lost time due to workplace injuries. Time savings become evident as materials can be loaded or unloaded swiftly, especially when compared to manual handling methods.

In addition to improving speed and safety, hydraulic scissor lifts enhance the precision with which materials are moved. The operator can finely adjust the elevation for tasks requiring careful alignment or positioning, supporting quality assurance in manufacturing and logistics.

- Reduced manual handling decreases injury risk.

- Quick access to elevated or ground-level positions increases overall efficiency.

- Precision controls assist with delicate processes or product handling.

- Versatility enables use across differing applications and environments.

- Space conservation is achieved by optimizing available vertical area.

Incorporating hydraulic lift tables is a strategic investment for achieving higher output and minimizing occupational hazards.

Load Capacity of Scissor Lift Tables

When considering a scissor lift or scissor lift table, understanding load capacity is crucial. These tables are engineered to safely support a range of weights, with models typically rated from 500 pounds up to several thousand pounds. This capacity ensures that they cater to diverse lifting requirements within manufacturing, logistics, and industrial maintenance environments.

Adhering to rated capacities is essential to maintain operational safety and avoid equipment damage or accidents. Operators should always be aware of the manufacturer's specified weight limits and ensure that all lifting applications stay within these boundaries. Scissor lifts and vertical lift tables are constructed with built-in safety margins to support maximum loads consistently.

Workplace Safety with Scissor Lift Tables

Scissor lift tables enhance workplace safety by providing a stable, controlled platform for vertical lifting. They reduce the need for staff to move heavy objects by hand, which minimizes the risk of musculoskeletal injuries.

A stable platform increases safety by preventing loads from tipping or shifting during movement. The height adjustability of these tables allows workers to maintain ergonomically sound positions, reducing the likelihood of back injuries caused by bending or awkward lifting.

Versatility in application further extends the safety benefits across multiple work scenarios, from assembly lines to warehousing and automotive repair. Efficient use of vertical lifting tables leads to fewer incidents and less work disruption caused by injury, making them an essential part of any safe material handling strategy.

Types of Scissor Lift Tables

Several configurations of scissor lift tables are available to meet a range of vertical lifting demands. The most common distinction is between static and mobile versions. For tasks that require stability in a single location, static scissor lift tables provide a robust, permanently positioned solution ideal for operations such as packing lines or storage. Information on different types is available on the scissor lift tables overview.

Mobile scissor lift tables, by contrast, are designed for flexibility and movement between locations. These mobile lift tables are equipped with wheels or casters, allowing users to transport heavy loads to different areas within a facility. The choice between static and mobile models depends on the specific workflow and the need for adaptability in the work environment.

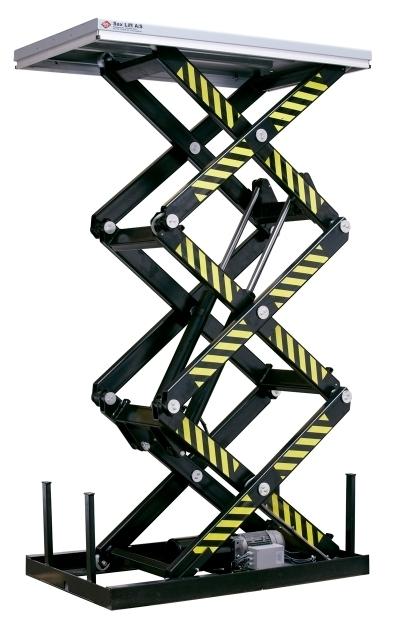

Double Scissor Lifting Table for Increased Height

A double scissor lifting table is engineered to deliver greater vertical reach than a standard scissor lift. This type of table has two stacked sets of scissor mechanisms, effectively doubling the maximum elevation obtainable from a single base footprint. The double scissor configuration is particularly valuable in settings where materials must be transported between significantly different height levels, such as in multi-story storage or production environments.

By using a double scissor lifting table, organizations benefit from increased flexibility without compromising load stability or overall safety. These tables maintain the same reliable functionality as standard versions, with the added advantage of extended lift height.

What is a Vertical Scissor Lift Table Used For

A vertical scissor lift table, whether standard or a double scissor lifting table, provides solutions for a wide range of lifting requirements. In warehousing, lift tables aid in loading and unloading shipments, accessing palletized goods on high racks, and optimizing storage through better use of vertical space. In manufacturing, workers use vertical lift tables to move heavy components between assembly stations at varying elevations.

Retail environments benefit from the use of scissor lift tables to replenish shelves, conduct inventory checks at height, or rearrange displays. The automotive industry utilizes vertical scissor lift tables for ergonomic positioning of vehicles or components during inspection and assembly. Construction projects also rely on these tables to safely move materials to higher floors or elevated workstations.

How to Choose the Right Hydraulic Lift Table

Selecting an appropriate hydraulic lift or vertical scissor lift table involves evaluating several important criteria. The most significant factors to consider are the required lifting height, overall load capacity, and the dimensions of the platform. An accurate assessment ensures the lift table chosen will meet the specific needs of the workplace, maximizing both safety and operational efficiency.

It is also crucial to determine the nature of the application: whether it requires frequent and heavy-duty lifting or occasional movement of lighter items. In addition, the question of mobility plays a key role. Fixed or static models are suited for repetitive tasks at a single site, while mobile variants are preferable where versatility is necessary. To assist in making the right choice, a comprehensive guide can be found at hydraulic lift tables.

Assessing power requirements is another step in the selection process. Hydraulic lifts can be manual, electric, or fully hydraulic. Each option provides different levels of convenience and performance suited to the complexity of the application. Finally, careful consideration must be given to the durability and construction materials, especially when selecting a double scissor lifting table intended for frequent heavy loads.

Factors to Consider When Selecting a Vertical Scissor Lift Table

A careful decision process is essential when selecting a vertical scissor lift table. The key factors include load capacity, platform size, intended purpose, mobility preferences, and power source. Ensuring the chosen lift table meets or surpasses workload requirements is necessary for workplace safety and long-term efficiency.

The surface area of the lift table must accommodate the largest items to be moved, while the overall table design should provide adequate stability for all anticipated tasks. If frequent relocation is part of the workflow, then a mobile lift table is the logical choice. Evaluating the specific setting—such as a warehouse, production line, or automotive shop—helps define which features are mandatory.

Importance of Height and Capacity in a Hydraulic Lift Table

Height and load capacity are pivotal when considering a hydraulic lift table for vertical lifting. Height determines the maximum elevation achievable, which is crucial for reaching elevated storage locations or for workflows that span multiple levels. Insufficient height can limit productivity and increase manual labor requirements.

Load capacity ensures the table can support the anticipated weight without risk of malfunction or injury. Operating a lift table outside its rated parameters can cause premature wear or lead to workplace incidents. It is essential to choose a vertical scissor lift table and, if necessary, a double scissor lifting table, that offers a safe and functional margin above the anticipated maximum load.

Optimal selection provides peace of mind for both operators and facility managers, reducing downtime, enhancing operational output, and maintaining consistent safety standards within demanding industrial settings.