Vertical scissor lift tables

Vertical Scissor Lift Tables - Vertical lifting

Searching for hydraulic lift tables with high load capacity? Double vertical scissor lift tables can be your solution, with their robust design, weight capacity of up to 4000 kg, and a plethora of safety features. These lift tables can greatly enhance productivity and safety in heavy-duty tasks, ensuring effortless handling. Dive deeper to explore the diverse models available, ways to customize for your specific needs, safety aspects, and where to find the most suitable lift table for sale.

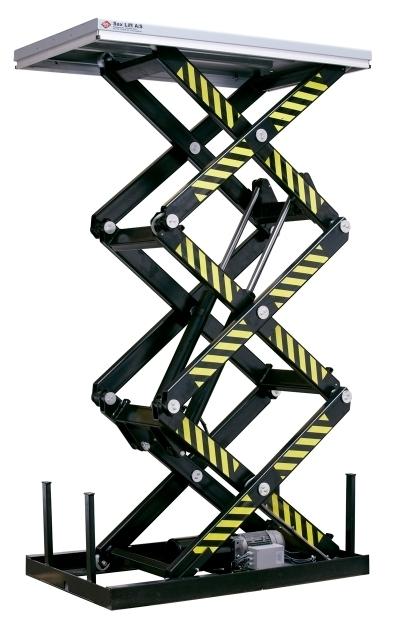

When it comes to handling heavy loads, nothing quite compares to the efficiency and versatility of vertical scissor lift tables. In the modern industrial landscape, the demand for equipment that can seamlessly bridge the gap between different working heights is critical. These ergonomic powerhouses are your go-to for both standard and bespoke applications. Whether you're working with a single, double, or even a triple scissor lift, you'll find that these lifts make your tasks easier, safer, and faster.

The primary advantage of vertical scissor lift tables lies in their ability to provide significant lifting height while maintaining a relatively small footprint. Unlike inclined ramps or hoists that require extensive space, a vertical scissor lift moves straight up and down, maximizing floor space utilization. With vertical scissor lift tables, you can raise and lower heavy loads with precision, reducing the risk of injury and enhancing productivity. Each lift is typically equipped with user-friendly controls and robust construction for long-lasting performance, ensuring that your investment pays dividends for years to come.

No matter your lifting needs, there's a lift table solution that's engineered just for you. From compact units designed for small workshops to massive industrial platforms capable of lifting automobiles or heavy machinery, the range is extensive. Invest in comfort, invest in efficiency - invest in a double vertical scissor lift table.

What is a Lift Table and How Does it Work?

So, you're wondering what a lift table is and how it works? Fundamentally, it's a platform that can be raised or lowered to different heights, powered by a hydraulic system. However, the engineering behind it is a blend of structural stability and fluid dynamics designed to handle immense stress.

They're commonly used in various industries for tasks such as lifting heavy loads, making them a versatile tool. At the heart of the machine is the scissor mechanism—a set of crossed arms that function like a pantograph. As the hydraulic cylinders extend, they push against these arms, causing the assembly to unfold and the platform to rise vertically. This vertical motion is guided and stabilized to ensure the load remains level throughout the transition.

Understanding the Design of a Vertical Scissor Lift Table

Imagine the power of a machine that can lift up to 4000 kg effortlessly. That's the vertical scissor lift table for you. It's not just about lifting power, though; it is about controlled power. The design incorporates a focus on safety and ergonomics, ensuring user protection and ease of operation. The structural integrity comes from high-quality steel profiles, often box-section or solid plate steel, which resist twisting and bending under load.

- Customization and accessories: You can tailor the lift table to your needs with solid designs and a variety of accessories. This might include turntables for rotating loads, tilting platforms for easier access to containers, or roller conveyors integrated directly into the tabletop for assembly line work.

- Safety features: With features like a 24 V DC control unit, overload protection, and adjustable safety trip bars, it's built with your safety in mind. The trip bars are particularly vital; located underneath the platform edge, they instantly stop the descent if they encounter an obstacle, preventing crushing injuries.

- Ergonomic design: The table's design prioritizes user comfort and efficiency. By allowing operators to adjust the work height to their specific physical requirements, these tables eliminate the need for bending, stretching, or stooping.

- Technical data and specifications: Understand the lift table's capabilities through detailed technical data, from lift stroke range to maintenance-free bearing surfaces. High-quality bushings and bearings ensure smooth operation and reduce the need for frequent lubrication.

This powerhouse is designed to work hard and smart, serving as the backbone of material handling in logistics, manufacturing, and warehousing.

How Hydraulic Systems Power Lift Tables

Understanding the power and versatility of a vertical scissor lift table is an impressive feat, but you might be wondering how exactly these tables work. The secret lies in their hydraulic systems. The principle is based on Pascal's law, where pressure applied to a confined fluid is transmitted undiminished in every direction.

When you operate double vertical scissor lift tables, a hydraulic pump—driven by an electric motor—pushes fluid (usually oil) into a cylinder. This pressure causes the piston inside the cylinder to extend. Because the cylinder is mechanically linked to the scissor arms, this extension forces the scissors to open, causing the platform to rise and lift the platform. This gives the tables their high load capacity.

Lowering the table is a gravity-assisted process. A valve opens to release the fluid back into the reservoir, and the weight of the platform (and the load) pushes the fluid out of the cylinder, allowing a controlled descent. As for safety and ergonomics, the tables are designed to lift heavy loads safely, reducing the strain on your body. Additionally, a pressure relief valve is included to prevent overloading, adding an extra layer of safety. This valve diverts fluid back to the tank if the pressure exceeds the safe working limit, effectively preventing the table from attempting to lift a load that is too heavy.

Common Applications for Scissor Lift Tables

Scissor lift tables, with their robust layout and impressive load capacity, cover a wide range of applications across various industries. Because vertical scissor lift tables can be installed in a pit or positioned directly on the floor, their utility is adaptable to almost any workflow.

They're particularly useful for:

- Pallet Handling: Triple scissor lift tables or high-lift double vertical models can easily manage heavy pallets, making your warehouse operations smoother and more efficient. They are often used as palletizers or de-palletizers, keeping the top layer of goods at an optimal working height for the operator.

- Assembly Lines: These tables adjust to the right height for workers, reducing fatigue and increasing productivity. In automotive or heavy manufacturing, the table can lift the product to the next level of a conveyor system or position it perfectly for a welder or assembler.

- Vehicle Loading and Unloading: With custom solutions, these tables help to load and unload vehicles safely, protecting your goods from damage. They serve as a bridge between the loading dock height and the truck bed, or even from ground level to the truck, accommodating different vehicle sizes.

- Workshop Applications: From welding to carpentry, these lift tables can bring your work to a comfortable height, enhancing ergonomics and efficiency. Heavy components can be positioned precisely, allowing for better accuracy in machining or repair work.

In short, scissor lift tables can revolutionize your operations, providing custom solutions for your industry-specific needs. They bridge vertical gaps in conveyor systems, serve as work platforms for personnel (when equipped with railings), and act as heavy-duty elevators for goods.

What are the Benefits of Vertical Scissor Lift Tables?

Have you ever wondered about the advantages of using vertical scissor lift table? While a single scissor lift is excellent for moderate height changes, a double vertical configuration utilizes two sets of scissors stacked vertically. This design allows for a much higher lift stroke relative to the platform length.

With their increased capacity for heavy loads and superior height reach, they could be a game changer in your work environment. A standard single scissor lift requires a long platform to achieve a high lift; a double vertical scissor lift table solves this by stacking the mechanism, saving valuable floor space while reaching new heights. Let's discuss how these lift tables can provide ergonomic solutions, and whether a standard or bespoke model is right for you.

Increased Capacity for Heavy Loads

When it comes to handling heavy loads, nothing beats the robustness of double vertical scissor lift tables. Specifically, in the UK and Europe, they bespeak the epitome of industrial innovation. They are engineered to handle dynamic forces and maintain stability even at full extension.

Here's why:

- Enhanced Load Capacity: Scissor lift tables provide the capacity to handle up to 4000 kg and beyond. That's a demonstration of their heavy-duty design. This capability allows for the movement of large machinery, pallets of raw materials, or bulk goods without strain.

- Efficiency: They use a hydraulic system to lift loads, saving you time and energy. The speed of lifting can be calibrated to match the production cycle, ensuring no bottlenecks occur in your workflow.

- Durability: The robust build guarantees they withstand the rigours of industrial use. High-tensile steel and quality powder coating or galvanization protect the unit from impact and corrosion.

- Customisation: You can opt for bespoke designs, tailoring the lift tables to your specific needs, such as reinforced platforms for point loads or stainless steel construction for hygienic environments like food processing.

Ergonomic Solutions for Work Environments

Imagine, as a worker, constantly bending and straining to manage heavy loads - it's not just tiring, but potentially harmful. Musculoskeletal disorders (MSDs) are a leading cause of workplace absence, often caused by repetitive strain and improper lifting techniques.

Double vertical scissor lift tables act as game-changers, turning strenuous tasks into easy ones. They're not just tools, they're ergonomic solutions for your work environment. They can lift up to 4000 kg, reducing physical strain and improving productivity. By maintaining the load at the "power zone" (between the knees and shoulders), workers can perform tasks faster and with less fatigue.

Their design complies with European safety standards (such as EN 1570-1), ensuring your safety is never compromised. Mobile, adjustable, and equipped with numerous safety features, these tables customize to fit your needs, creating a sustainable working environment where employee well-being is prioritized.

Standard vs. Bespoke Models: Which is Right for You?

Choosing between standard and bespoke models of double vertical scissor lift tables might feel overwhelming. The market offers a vast array of "off-the-shelf" products, but sometimes unique challenges require unique solutions.

But don't worry, we're here to help.

Standard models are ready-to-use, offering high quality at a lower cost. They are engineered based on common industrial requirements regarding platform size, lift height, and capacity. They're perfect if you're after efficiency and economy, and your application fits within typical parameters.

Bespoke models are custom-made to suit your specific needs. They're the go-to if you've got unique requirements that standard models can't meet. This could involve specific platform geometries (U-shaped, E-shaped), specialized control logic for automation integration, extremely high cycles per hour, or specific environmental protections (ATEX rated for explosive atmospheres).

Standard models usually have quicker delivery times. But if you're not in a rush, bespoke models are worth the wait to ensure perfect integration into your facility. Remember, either choice provides the key benefits of these tables: improved safety, higher efficiency, and reduced worker fatigue.

How to Choose the Right Scissor Lift Table for Your Needs?

Choosing the right scissor lift table for your needs can be a game-changer. It is not merely about buying a piece of equipment; it is about selecting a partner for your production process. A mismatch in specifications can lead to operational inefficiencies or safety hazards.

Start by evaluating your lifting requirements and then examine the capacity and power specifications of various options. Don't forget to compare double and triple scissor lift tables to find your perfect match regarding the closed height versus the maximum lift height.

Assessing Your Lifting Requirements

Reflecting on your lifting requirements? Selecting the right scissor lift table isn't as intimidating as you might think if you break it down systematically. It's essential to assess your needs accurately to guarantee a safe and efficient working environment.

Here are four key factors to take into account:

- Type of Material: What're you lifting? The size, weight, and type of material greatly influence your choice. Is the load stable? Is it a fluid? Does it have a center of gravity that shifts? Dealing with a distributed load is different from dealing with a concentrated point load.

- Frequency of Use: How often will the lift be used? Regular, heavy use demands a robust, durable model. If the lift operates continuously in an automated line, you need a heavy-duty cycle rating, whereas a lift used once a day for maintenance requires different specs.

- Work Environment: Is it a warehouse, construction site, or a retail store? Different environments require different specifications. Outdoor use requires weatherproofing; food industries require stainless steel; chemical plants may require specific seal materials for the hydraulics.