Lift tables

Hydraulic Lift Tables & Scissor Lift Tables at Sax Lift UK

Your hydraulic lift tables and scissor lift tables available at Sax Lift UK are essential tools for raising or lowering heavy-duty tasks to varying heights. Whether you require a mobile or static model, it's important to take into account the lifting capacity, height, and installation site to meet your work needs. Don't forget about safety features compliant with all necessary regulations and regular maintenance for long-term efficiency. So, stick around to get all the details to enhance the safety and efficiency of your operation!

What are Hydraulic Lift Tables?

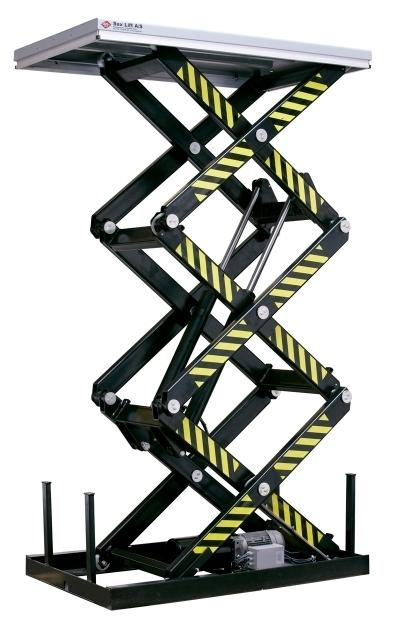

Hydraulic lift tables are versatile pieces of equipment designed to raise or lower heavy loads to desired heights.

They're built around a scissor lift mechanism, powered by a hydraulic cylinder. You can easily adjust the platform's height, making it ideal for tasks where you need to work at varying levels.

These tables have a specified load capacity, so you must guarantee that you don't overload them.

The operation of a hydraulic lift table is generally straightforward, but you'll need to familiarize yourself with the specifics of your model to use it safely and effectively.

Whether you're lifting boxes in a warehouse, working on an assembly line, or doing home renovations, a hydraulic lift table can make the job easier and safer.

How to choose a suitable hydraulic scissor lift table

When choosing a hydraulic scissor lift table, you'll need to take into account several essential factors.

The lifting and loading capacity, as well as the lifting height, are all crucial to guarantee it suits your specific needs.

Additionally, think about where it'll be installed and if it's for stationary use.

Lifting capacity

Choosing the right hydraulic lift table for your needs involves several factors, but one of the most critical is lifting capacity. You need to verify that your scissor lift table can handle the weight you plan to lift.

-

Mobile scissor lift tables are great for lightweight tasks and easy movement. They typically support up to 1000 kg.

-

For heavier duties, you might want to take into account hydraulic scissor lift tables with a capacity of up to 8000 kg. These static models are sturdy and suitable for continuous heavy-duty operations.

-

Don't forget to take into account the safety mechanisms. A table with safety features like emergency stops and pressure relief valves can prevent accidents and damage.

Lifting height

After settling on the lifting capacity, another factor to reflect on is the lifting height. This is determined by the scissor mechanism in your hydraulic platform. Standard hydraulic and vertical high lift tables offer varying lift heights, so you'll need to evaluate what's ideal for your tasks.

For instance, if you're aiming for ergonomic efficiency, a table that adjusts to multiple heights is perfect. Here's a quick comparison:

| Lift Table Type | Lift Height | Best Use |

|---|---|---|

| Standard Hydraulic | Up to 2.5m | Light to high weight handling |

| Vertical High Lift | Up to 5.1m | Specialised tasks requiring high lift |

Installation site

Selecting the right installation site for your hydraulic scissor lift table is a crucial step. Consider whether a static or mobile model best fits your needs.

- Static Lift Tables are sturdy, offering larger platforms and higher load capacities. They're best used where heavy lifting is a routine task.

- You can install them permanently or in pits for barrier-free access.

-

Mobile Lift Tables are versatile, designed for easy transport and short-distance movement. They've ergonomic handles and safety mechanisms like locking brakes to secure the table during use.

- Regardless of the type, verify the installation site is level, clear of obstructions, and allows safe operation of the hydraulic platform lifts.

Loading capacity

Understanding the load capacity of your hydraulic scissor lift table is a key factor in making an informed choice.

Loading capacity refers to the maximum weight your lift can safely handle. It's vital to take into account the heaviest load you'll be lifting and make certain it falls within this limit.

Hydraulic scissor lift tables are designed with various maximum lifting capacities. Some are suited for light-duty lifting, while static scissor lift tables can handle up to 8000 kg, perfect for heavy-duty lifting tasks.

Always verify the weight capacity of your chosen lift table aligns with your needs to prevent overloading and potential damage.

Stationary use

If you're primarily planning to use your hydraulic lift table in a stationary manner, it's best to evaluate the static models. These scissor tables are designed for fixed installations, supplying higher load capacity than their mobile counterparts.

-

Ergonomic Design: Static scissor lift tables are designed to raise heavy loads to comfortable work heights, reducing physical strain.

-

Capacity: These lifts can support substantial weights, making them perfect for heavy-duty applications.

-

Safety: Built with safety in mind, static lifts come with features like emergency stop functions and non-slip surfaces.

Lifting function

Consider your lifting needs carefully as you navigate the options for hydraulic scissor lift tables. The product you choose should align with your specific requirements.

The lifting mechanism of hydraulic scissor lifts is an essential aspect to evaluate. The lift means, or the method by which the table elevates is typically powered by hydraulics.

Consider the range of lift, from the minimum to maximum height. A broader range offers more versatility.

While safety will be discussed more in-depth later, it's worth noting the importance of safety features in the product's design. Robust safety measures can greatly reduce the risk of accidents.

Safety Features

While selecting a hydraulic scissor lift table, don't overlook the importance of safety features. They're essential to prevent accidents and guarantee compliance with regulations.

- Safety Mechanisms: Look for tables equipped with hydraulic catch cylinders to prevent sudden drops, and pressure relief valves to manage overpressure. Heat protection functions are also crucial to prevent system overheating.

- Compliance: Confirm your chosen product adheres to the European Standard BS EN 1570-1:2024 for safety.

-

Maintenance: Regular maintenance is key to longevity and safety. Keep a maintenance log to track service and inspections.

Our lifting tables in detail

Although you may find a multitude of lifting tables on the market, our range stands out for its diversity and quality.

As a reputable lift table supplier in the UK, we offer a wide variety of scissor tables, including mobile scissor lift tables, all built with precision-engineered cylinders.

What's more, our tables are customisable to your specific needs.

Safety is paramount in our design. Our tables come equipped with safety mechanisms such as hydraulic catch cylinders to prevent sudden drops.

We also offer mobile scissor lift tables, perfect for tasks that require manoeuvrability.

Our commitment to quality and safety positions us as a leading provider of lift tables, meeting and exceeding industry standards.

| Type of scissor lift platform | Features |

|

|

|

|

Low profile scissor lift table

|

|

|

|

|