The scissor lift table is an efficient way to get your work done. With this mechanical lifting platform, you can raise and lower it at any desired height without having to physically carry out tasks like in the past! Not only does that optimize ergonomics but also balances vertical distances which makes workspace flexibility much easier than ever before

Read more about:

- How they can be used,

- What you should know about your own processes before purchasing one, and

- How they are used and maintained in a safe manner.

Content:

1. Basics of lift tables

2. Models

3. Add-on equipment

4. Bespoke solutions

5. Functions and safety

6. Training and operation

7. Maintenance

8. Mobile models

What is a lift table?

The scissor lift table is a versatile tool that can be used for many different purposes. It's particularly popular in manufacturing, retail and food industries where it allows workers to work more efficiently with heavy materials without risking injury.

Lift tables come equipped standardly with lifting capacities up to 7000kg (15 PB!), total heights over 4 meters

With a large variety of options, custom-made for any need and available in scissor lift trolleys and table top plates with different sizes ranging from 90 cm to 4.4 meters long; our products is an ideal solution when it comes to lifting heavy loads

Basics of Lift Tables

There are five basic details that will help you get started when searching for a lift table.

- The lifting height

- The top plate size

- The weight of the heaviest load

- Information about the installation point and

- The method of loading and offloading.

Lifting height

When choosing the best lift table for your needs, there are a few things that should be considered. First and foremost is whether you want to install it on floor or if it will need access from below ground level?

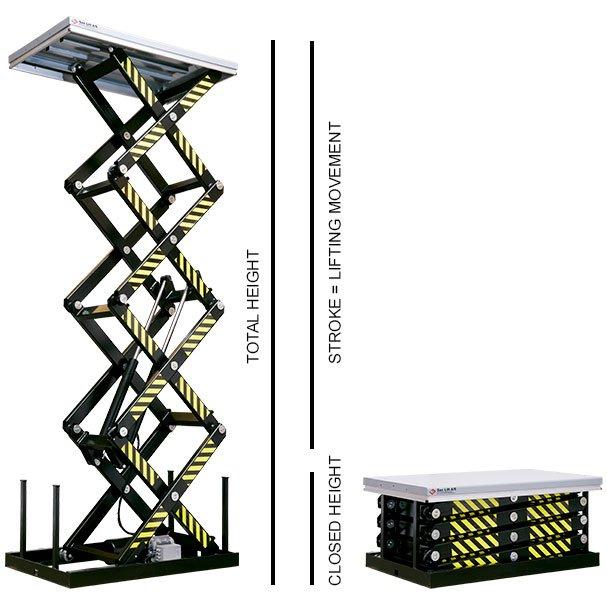

Stroke: Lifting movement. The lifting height when the table is installed in a pit.

Closed height: The height of the lift table when it’s closed.

Total or max height: Stroke + closed height. The lifting height when the table is installed on floor.

What's also important here: Does this application require heavy duty use such as lifting large items frequently.

The top plate

When handling large items, make sure that your lift table has enough space to avoid trapping when lowering it. The size of the top plate should be at least slightly larger than what you are lifting so there's no risk in bottoming out on anything during transport and loading procedures

If you need a lift table with railing and gates, the lift table must be larger than the largest item you plan to lift with it, as the barriers will take up some of the top plate’s surface.

Top plates can be made a bespoke size, but the extension may affect the capacity of the lift table. Please contact us if you need a lift table with a bespoke top plate size, and we will find a good starting point for your application.

Table capacity

A lift table’s capacity is determined by the weight of the load. For even loads it’s the lift table’s stipulated safe working load (SWL). For uneven loads you might have to look for a lift table with extra capacity.

What affects safe working load?

The stipulated capacity indicates the lift table’s capacity center loaded, with an item that is within the table’s edges.

If you plan on using the lift table with an uneven load, or if you are looking for a top plate that is extended, you should start by looking at lift tables with extra capacity.

A load should never hang over the edge of the lift table. There is a safety trip bar hinged under the outer edge of the lift table, and it is this trip equipment that stops the lowering movement in case anything or anyone reaches under the lift table when it's in use.

A load should always be same size or smaller than the lift table’s top plate, and not hang over the edge on any side. If a load is hanging over the lift table’s edge, the safety trip bar will not cover this part and there is a risk of trapping.

Does my lift table require reinforcement?

Lift tables are designed to be loaded over the short side. Reinforcement of the top plate may be needed when a table is loaded over the long side.

Contact Sax Lift to find out whether your installation requires a reinforced top plate.

Lifting floor to floor

A vertical and high lift table is ideal for the quick leveling of a long distance between a basement / street level and a first floor.

Double, triple and quadruple scissors make the lift table high in its closed position, and a pit installation is recommended on sites where the lift table is loaded with a manual pallet truck.

Safety barriers: gates and railings

The barriers can either be the standard open type, or the type that is enclosed with perforated steel, giving them a neat look and extra lifting safety.

The standard height of handrails is 1100 mm. They can be made higher if needed, but not lower. Gates can be single door or split door, and they can be made to open horizontally or vertically. The most common solution is a gate that opens horizontally, away from the lift table.

We recommend consulting an expert before ordering a lift table with gates and railings. Sax Lift can help you with finding the correct type of gates and railings and provides advice for a safe installation.

Bridging plates and loading flaps

A bridging plate can have a double purpose. It can be used for bridging the distance between a lift table and a floor or a delivery vehicle, and as a barrier that keeps goods from sliding off the lift table.

Bridging plates can be manual or automatic.

Automatic controlling is recommended for very large bridging plates which often are too heavy for manual handling.

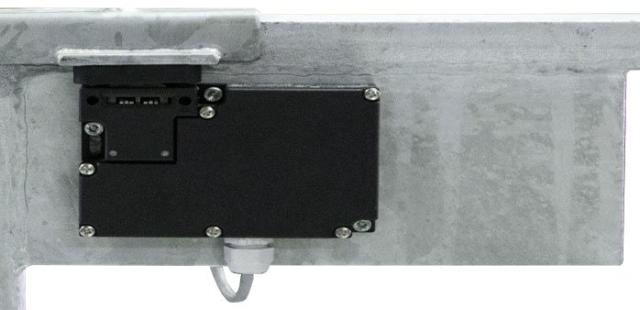

Interlock - electrical safety

An electrical safety lock, interlock, minimizes this risk of injury and damage caused by falling.

The interlock system has three basic functions:

- All gates are always automatically locked.

- A gate can only be opened when the lift table is on level with it.

- If a gate is not closed and locked, the lift table will stay in one place until all gates are properly closed.

Installing your table next to a wall

The fixed bearing side of the scissor is placed furthest away from the wall.

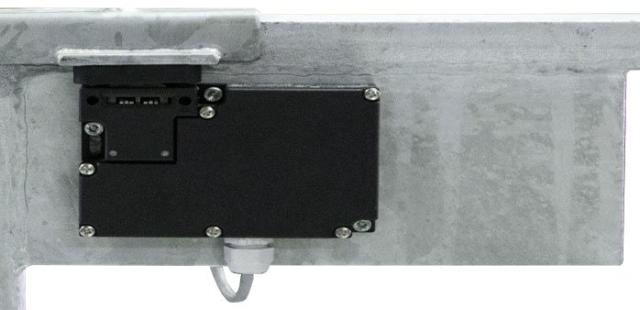

The pump and control box are always mounted between the scissors that are fixed to the base frame, which gives easy access for maintenance and repairs.

Installation point – what is required?

- Even and stable floor - must be able to carry the lift table's net weight + safe working load.

- Sufficient lighting - the operator must be able to see the lift table at all times.

- Unobstructed space on all sides of the table.

- Correct temperature - not higher than 50 degrees Celsius.

- Free space of 0.5 metres around the table.

- If the installation surface is uneven, a bespoke steel chassis can be built under the lift table to level it out

- If a 0.5 m distance to the lift table is not possible during operation, please contact Sax Lift for further advice.

Sketches, drawings and measurements of the installation point and the work flow are always very helpful

Method of loading and offloading

The method of loading and offloading determines which type of table suits you best.

Manual pallet trucks, pallet stackers and forklifts have all a different vertical reach and work with different models. See all lift table models below.

If you can install the lift table in a pit, the lift table can be loaded with any equipment.

Lifting height and installation in a pit

When a lift table is installed in a pit the top plate is flush with the surrounding floor. And in ground level lift tables are easy to load and offload with a manual pallet truck, and can be tucked out of the way when the floor space is needed for other activities.

When a scissor lift table is installed in ground the total lifting height is the stroke of the lift table. Contact us for detailed instructions and plans for building a pit and for finding a lift table that fits your site.

The pit should always be slightly larger than the lift table its closed position. For a successful in ground scissor lift installation the pit measurements are:

- Length of lift table + 30mm.

- Width of the lift table + 30mm.

- Minimum height of lift table + 20mm for adjustment.

There should be a drain at the bottom to lead water out of the pit.

A pit design should also include a pipe to lead the electric cables out of the pit.

An external power pack makes maintenance easier and keeps the pump safe in case water collects at the bottom of the pit. The power pack, including the pump and the electrical control box, can be installed relatively far away from the lift table – where it is easiest to access for maintenance.

You may even find the space for it in a separate room, up on a wall or in the ceiling, but it shouldn't be installed higher up than 4m from the base frame of the lift table.

The hand control panel for the use of the lift table must always be at a location where it's visible from all sides of the table.

Sax Lift provides steel pit edges for a neat and durable finish along the edge of the pit.

Models and configuration

- Single scissors

- Vertical lift tables

- Horizontal lift tables

- Low profile lift tables

- Power - a lift table with the right configuration

Single scissors

Single scissor is the most common lift table, with lifting power up to 7.000kg in the standard range.

High Lifting

The vertical scissor lift table takes you to new heights with maximum lifting heights between 1780mm-4200 mm.

Lift Table pallets

Low profile lift tables are designed for pallet handling and can be easily loaded with a hand pallet truck.

Heavy Lifting

Horizontal Tandem scissor lift tables are ideal for heavy lifting, long items or several pallets at once.

Power configuration options

Lift tables are available in different power configurations.

1x230V – standard household power

Most Sax Lift heavy-duty tables can be delivered with a 1x230V 50Hz configuration.

This requires a special pump and it may slow down the lifting speed.

3x230V

Sometimes a three-phase configuration is used with 230V power.

Please inform us if this is a requirement at your installation point and we can install the right configuration already at the factory.

All our three-phase tables are delivered with a red, 5-pin CEE-plug.

3x400V

Most of our motorized lift tables are by standard 3x400V 50Hz.

All our three-phase tables are delivered with a red, 5-pin CEE-plug.

24V battery

If you plan to move the lift table around, a wireless solution without a power cord is the solution for you.

We can deliver a lift table with a 24V pump and a battery.

The lift table can be charged when it’s not in use, and the battery has an indicator showing when it needs charging.

Add-on equipment for standard models

Add-on equipment can make your everyday work faster and easier. If you’re uncertain which add-on equipment is the correct one for you, please contact us and we’ll be happy to help you.

- Limit switch

- Self-leveling

- Loading flaps and ramps

- Handrails

- Interlock

- Tilt and turn

- Curtains

Limit switch, upper and lower

Limit switches can be used for adjusting the heights of the lift table. When a limit switch is triggered, it stops the movement of the lift table. Both types of limit switches are adjustable.

An upper limit switch is used for stopping the motor at an adjusted height. A limit switch is recommended when a lift table is used together with an adjoining machine or shelving and the maximum height is not varying.

A lower limit switch is used for adjusting the closed height of the lift table. It can make the closed height higher than what it is by standard. Please note that building longer support legs on the lift table is recommended when the lift table is installed in a pit and there are people walking or vehicles driving over the lift table when it’s closed.

Bridging plates / loading flaps

Loading flaps can be used for bridging a distance between the lift table and a vehicle or another level. Loading flaps may double as a barrier that keeps the load in place.

There are both manual and automatic options for the bridging plates, and they can be programmed into the interlock system.

Self leveling lift tables

If you are looking to lift and lower your lift table automatically (overriding the dead-man’s switch), an inductive sensor is the solution for you.

Inductive sensors can be used for stopping the lift table on a preprogrammed level in the middle of the lifting and lowering cycle – for example with and adjoining shelf or another machine.

There are numerous options for automating the movement of a scissor lift table. Please contact Sax Lift to find out the option that suits you best.

Railings and gates

Railings and gates are used for keeping goods from falling over the edge of the lift table.

Ramp

Sax Lift low profile lift tables come with a ramp by standard. Ramps are available for other types of tables as well, but have to be built for the specific installation. The angle of the ramp determines how much space there needs to be between the ground and the base of the handling equipment you use. Please contact Sax Lift for advice if you require a bespoke ramp.

Interlock system

An electrical safety lock (interlock) minimizes this risk of injury and damage caused by falling.

The interlock system keeps all gates and doors automatically locked, and prevents the movement of the lift table in case there is any risk of injury. Bridging plates can be programmed into the interlock system.

An interlock system can be delivered installed on the lift table, or prepared for installation on existing doors you have on site. It can be installed on any type of gate or door.

Control panel options

Depending on the installation you may need a special control panel.

- Foot pedal: up and down pedals and emergency stop.

- Hand controller with keys: for installations where access needs to be restricted.

- Bespoke colours, functions and materials: please contact us to enquire for bespoke versions of the control system.

Turntable

A turntable can be used for rotating the goods for easy access from all sides. A turntable can be either manual or automatic – depending on how you intend to use the lift table.

If you need to stop the turntable at certain positions, the manual turntable can be delivered with a mechanical lock stop. The automatic lift table can be preprogrammed to stop at certain intervals.

The most common turntable shapes are round and rectangular. We can deliver a turntable ready for the attachment of your own equipment on top - please contact us for details.

Casters frame and truck handling chassis

If you plan to regularly move your scissor lift table from one spot to another, a casters frame or a truck handling chassis are the solutions for you.

A casters frame makes it easy to push your lift table from one location to another. Contact us about motorized drive!

With a truck handlings chassis you can move a lift table with a pallet truck or a forklift. A truck handling chassis can be made any height - contact us to find out more.

Tilt

A tilt can be used for lifting goods in an angle. This gives you an easy access to the surface you are working on, or makes it easier to roll goods off the lift table.

A tilt works with a dead-man’s switch, and can have either its own control panel, or the controls for the tilt can be integrated in the hand controller that is also used for lifting and lowering.

Tilt and turn can also be combined.

Bellows and steel mesh curtain

A skirt around a lift table protects the scissors of the lift table from outside objects. There are two options for a lift table skirt: a PVC bellow or a steel mesh curtain.

All Sax Lift bellows are made to fit and are installed behind the safety trip bar. A bellow protects the scissors and the power pack against water splashes, tools and other items that may fall under the lift table. Please note that a bellow isn’t completely water- and airtight. There needs to be a flow of air in and out of it.

A steel mesh curtain is installed either behind the safety trip bar or on the edge of the lift table. A mesh curtain is good for keeping tools and other items from falling under the lift table.

Rollers - manual and automatic

Rollers make handling of goods even more efficient and easy, and removes the need to lift goods up off the table.

Any type of rollers can be fitted on top of a table: conveyor rollers and steel ball rollers are the most typical types we provide. The conveyor rollers can be either manual or automatic.

Bespoke solutions

Our Lift tables are manufactured in all shapes and sizes depending on the job it is intended for. Bespoke lift tables go beyond the sizes and capacities of our standard selection, and can have functions ranging from the basic lifting and lowering to tilt, turn and motorized drive.

If you want to know more about customised lift table solutions, click the button

Hazardous environments

Did you have a specialist on site to determine which ATEX-zone your lift table’s installation point belongs to? A working environment may be hazardous for two reasons: dust and gases. The zone classification depends on the saturation of either matter in the lift table’s surroundings.

Sax Lift provides ATEX zone 1+21 and 2+22-rated lift tables where the power pack must be installed outside the ATEX zone. All ATEX tables are delivered with an extensive documentation package.

An ATEX-rated lift table can be installed in hazardous environments where there is risk of explosion. The components of an ATEX-rated table are secured against sparks and the ignition in the atmosphere is avoided.

Environments with moisture – how to extend a lift table’s lifetime

A standard painted steel solution can be installed outdoors, but the lifetime of the machine will be limited due to corrosion. Sax Lift offers three options that can extend the lifetime of your outdoors lift table:

- C3-paint –environments with little moisture

- Galvanisation – environments with moisture

- Stainless steel – wet environments

All electrical parts are IP54-classified by standard and tolerate water sprays and light dust. A higher IP-class is possible as per your requirements.

Hygienic environments – stainless steel solutions

We provide stainless steel lift tables for your food production and other hygienic environments. To maximize the cleanliness in your production or logistics, the lift table can be filled with food-grade hydraulic oil.

Food-grade hydraulic oil doesn’t contaminate the environment and can be hosed off with water in case of leaks. If you don’t need a fully stainless lift table, parts of a lift table can be made stainless.

For example, a lift table with a galvanized base and scissors combined with a stainless steel top plate comes at a lower cost than a fully stainless solution.

Temperature of the environment

All our standard lift tables work in environments between -30 and +50 degrees Celsius.

For colder environments the hydraulic oils must be changed to a type that tolerates -30 degrees Celsius and colder.

The room temperature must never exceed +50 degrees Celsius.

Mobile lift tables – manual and electrical

A mobile lift table is ideal when you frequently lift and move around heavy loads. A mobile lift table protects your physical well-being and can speed up your working process.

You avoid making heavy lifting by hand, and the need for reloading is removed when you can simply move the table around.

Sax Lift manual mobile lift tables range between 150-1000 kg in capacity, and come in various sizes and lifting heights. The smallest, lightweight mobile lift tables weigh only 40kg and can easily be transported in a van from one location to another.

Please consult your workplace for the maximum weight of items you are allowed to lift by hand.

Manual mobile lift tables

Sax Lift offers manual mobile lift tables both with a screw-type mechanical lift platform and with hydraulic lifting. The mechanical model, I300, is lifted and lowered using a handle. I300 is our most economical solution, and is suitable for environments where hydraulics are not allowed.

We offer several models of manual mobile lift tables in the hydraulic range, ranging between 150 kg to 1000 kg. The hydraulic manual lift tables are lifted with a foot pump and lowered with a handle. The top plate sizes range from 700 x 450 mm up to 1200 x 800 mm. Please visit our website to see all the options available.

Electrical mobile lift tables

An electrical mobile lift table removes all physical effort from your work flow.

An electrical mobile lift table comes with a 12V battery and is operated with a dead-man’s switch.

The battery has an indicator for when it needs to be recharged. A mobile lift table can be charged when it's not being used.

You can use the downtime to charge your lift table - over night or between shifts. 1x230V power is used for charging an electrical lift table.

Operation manual and training of employees

The workplace authorizes all personnel using a lift table to do so. The authorization is an internal process, which means that the employer makes sure that all employees understand the guidelines of using a lifting table safely.

All our tables are delivered with a table-specific operation manual which contains detailed instructions for all the functions on the lift table and for the safe use of these functions.

Please take good care or the operation manual, and keep it at a place close to the lift table, where it is easy to access for both operation and maintenance instructions.

Simple tips for the safe operation of a scissor lift table

To have the safest possible working conditions, you must follow all the instructions in the operation manual of that lift table. In the following you can find the main points for a safe operation of a standard lift table with only standard functions.

Take good care of your lift table – check the safety trip function daily and don’t toss the hand control unit around or break it in any other way. Follow the daily, monthly and yearly maintenance schedule that can be found in the operation manual. If you suspect a fault in your lift table, don’t hesitate to contact Sax Lift or your service partner.

- Never enter or reach under the lift table unless it’s mechanically locked in place.

- Never place other items or objects under the lift table.

- The working environment must be regularly cleaned, under 50 degrees Celsius and well lit.

- Wear safety footwear when working with a hydraulic lift table.

- There should be a minimum of 0,5 m space on all sides of the lift table.

- Always make sure that the load cannot fall or slide off the lift table.

- Personnel are only allowed to walk on the lift table when it is not in moving, and you must make sure they cannot fall off of the table or trip over while doing so.

- The operator of the lift table must always have an unobstructed view of the lift table on all sides at all times. The control panel must be placed so that the operator can use the up and down functions, as well as the emergency stop function while observing the table.

- When there’s a long pause in operation, keep the lift table in its closed position.

Practical advice for the use of your lift table

Receiving and offloading the table: All our standard lift tables are delivered CE-marked and ready for use. Please read below for step-by-step instructions for what is required from you when we deliver a lift table.

Before offloading the delivery: Examine the lift table for possible transport damage before offloading. If there are any visible damage this must immediately be noted on the consignment note. Contact Sax Lift A/S right away for further instructions.

If there are no transport damages the table can be offloaded – still wrapped in its original packing – to the installation point. The lift table can be moved with a pallet truck, a fork lift truck or a crane. When the lift table has been positioned at the installation point, the wrapping can be removed.

Electrical work

A CEE-plug is installed on the lift table already at the factory but the lift table can be wired directly to power if this is preferred. Any electrical connection of the lift table must be made by an authorized electrician. The main power should be provided with lockable main power switch.

Safety gear

When moving, installing or servicing the lift table, it is advisable to use safety footwear. Local conditions regarding security equipment should also be followed.

Moving the lift table with a crane or a forklift using eye bolts

The lifting eyes are delivered with the lift table and can be found under the top plate. For moving the lift table, the eye bolts must be screwed into the corner holes on the lift table’s top plate. This way the top plate and the base/base frame are fixed together (see picture) and the lift table can be lifted and transported by using the lifting eyes.

If there are no threaded holes or lifting eyes on your lift table, please refer to the operation manual or contact Sax Lift.

Before taking the lift table to use

- Read the operation and maintenance manual thoroughly. Contact Sax Lift if anything is unclear.

- The lift table must be placed on a flat, solid and level floor. The base frame is not self-supporting. The distance to other objects should be at least 0.5 meter.

- The installation area should be well lit during installation and at future use.

- When the lift table is placed at the installation area, the lifting eyebolts are removed before the lift table is taken to use.

- The lift table is secured to the floor with expansion bolts using the holes in the base frame.

- Before connecting the lift table to power, please make sure the lift table configuration matches main power on site. The power configuration of your lift table can be found in the operation manual and on the electrical control box next to the pump.

- A risk assessment must be made on site after installation.

Receiving lift tables with casters and forklift handling chassis

If your lift table is delivered with an add-on chassis, the chassis supports the base frame and doesn’t require securing to the floor.

The lift table must be unloaded and in its closed position when it is being moved. The floor under the lift table must be even and stable, and it must be able to carry point pressure from the casters and the legs.

Always activate the brakes on all swivel casters when the lift table is in use. The brakes are activated by pressing the lock brake down with your foot.

Loading and offloading goods

A lift table can be loaded and used in almost any way.

Some methods of loading and offloading require extra reinforcement in the structure, and some require a special installation or a ramp, like pallet truck or other equipment with low chassis.

Installing the lift table in a pit makes it flush with the surrounding floor. You should still load it over the short end where the scissors are attached to the base frame. If you’re looking to load over the longer side of the lift table, the top plate may need reinforcement. Please contact us to find out more.

A low profile lift table with a ramp allows access without installation in pit. With most models the ramp is 900mm long and has the same width as the lift table. Please notice that we can build a ramp for any of our lift table models.

On standard single scissor and vertical lift tables the ramp needs to be very long if a pallet truck is used. With standard sized tables a pit installation is preferable.

U- or E-shaped low profile lift tables save space - there is no need for a ramp at all.

All low profile solutions come with an external power pack.

Forklift, crane and other method of loading evenly from above

There are no limitations to loading a lift table with a forklift, a crane or any similar method. Any lift table can be loaded using these methods.

Lift table loaded from the short side vs loading from the long side

A hydraulic lift table is designed to be loaded over the short side where the scissors are fixed to the base frame. Loading over the long side is not ideal as sideways forces are affecting the scissor frame. For loading over the long side the top plate usually needs to be reinforced.

Loading over the long side – which precautions should be taken

If you’re planning an installation with loading over the long side - especially with a pallet truck or similar - please contact Sax Lift for advice. We can make your solution durable in the use it is intended for.

Casters frame

A standard casters frame has two fixed casters and two swivel casters with brakes. Polyethylene wheels make even the heavier lift tables easy to push around.

The swivel casters of a casters frame must be locked while the table is lifting and lowering. The brakes of the swivel casters are pressed down and released by foot.

Truck handling chassis

A truck handling chassis makes it easy to move your lift table around with a forklift or a pallet truck. This can also be the solution for you when you need a lift table that is permanently raised up from the floor.

Movable lift tables: casters chassis and truck handling chassis

If you plan to move your table from one spot to another, a casters frame or a truck handling chasses are recommended. The chassis supports the weight of the lift table and the load, and the floor below must be able to support the point pressure from the chassis.

Movable lift tables: casters chassis and truck handling chassis Safety-tip: If the lift table is moved from one place to another while loaded, it should always be in its closed position during the movement.

Maintenance and repairs

An electro-hydraulic scissor lift table has a long lifetime when used correctly and serviced periodically. Investing in a service contract may save you the cost of a new lift table. There are safety and maintenance precautions that need to be take care of daily, monthly and yearly. Some points can be covered internally in your own organizations, while others require the assistance from a specialist.

Please refer to your lift table’s operation and maintenance manual for detailed information about maintenance. You should always keep log in the table’s specific manual about all maintenance and repair work done on the lift table.

Spare parts

Sax Lift wants to keep your production and processes moving and offers most spare parts for delivery in 1-3 days. To order spare parts for your lift table, please provide us with the lift table’s serial number. If this is not available, please inform us about the model and the production year.

All information can be found on the silver machine plate attached to the scissors or under the top plate.

Identifying a lift table for maintenance and inspections

All substantial maintenance work on the lift table must be logged in the operation and maintenance manual for that specific table. It is important that you take good care of the manual and keep it at a place where it is at hand for maintenance and inspections.

Every manual includes a serial number, which is matched on the lift table’s machine plate. The machine plate is a silver-colored sticker attached to the lift table’s scissors or under the top plate.

If your machine plate goes missing or gets damaged, please contact Sax Lift for instructions.

Preparing for maintenance

You should never reach or enter under the lift table before the lift table is locked in place with the maintenance safety legs.

- Raise up your lift table using the white “up”-button. You only need to lift it high enough to place down the maintenance safety legs. Use a tool to push them down.

Never reach under the table before it’s locked in place. Always use safety legs on both sides. - Use the black “down”-button to lower the lift table’s full weight onto the maintenance safety legs. PLEASE NOTE: precautions before maintenance:

- When working on hydraulics: when the lift table is resting on the maintenance safety legs, press the black “down”-button 20 more seconds to remove pressure from the hydraulic system.

- When working on the electronic system: when the lift table is resting on the maintenance safety legs, disconnect from main power. After completing maintenance, please test the lift table using the hand controller before removing the maintenance safety legs.

- After turning the safety legs up you should no longer reach or enter under the lift table.